5050 with 3Chips Growing LED Strip Light

Specifications:

1. LED Chip: SMD 5050 with 3 Chips ( Super high brightness )

2. Emitting Color: Red + Blue, Red + Blue + White etc (LED Color combination and ratio can be customized as the request )

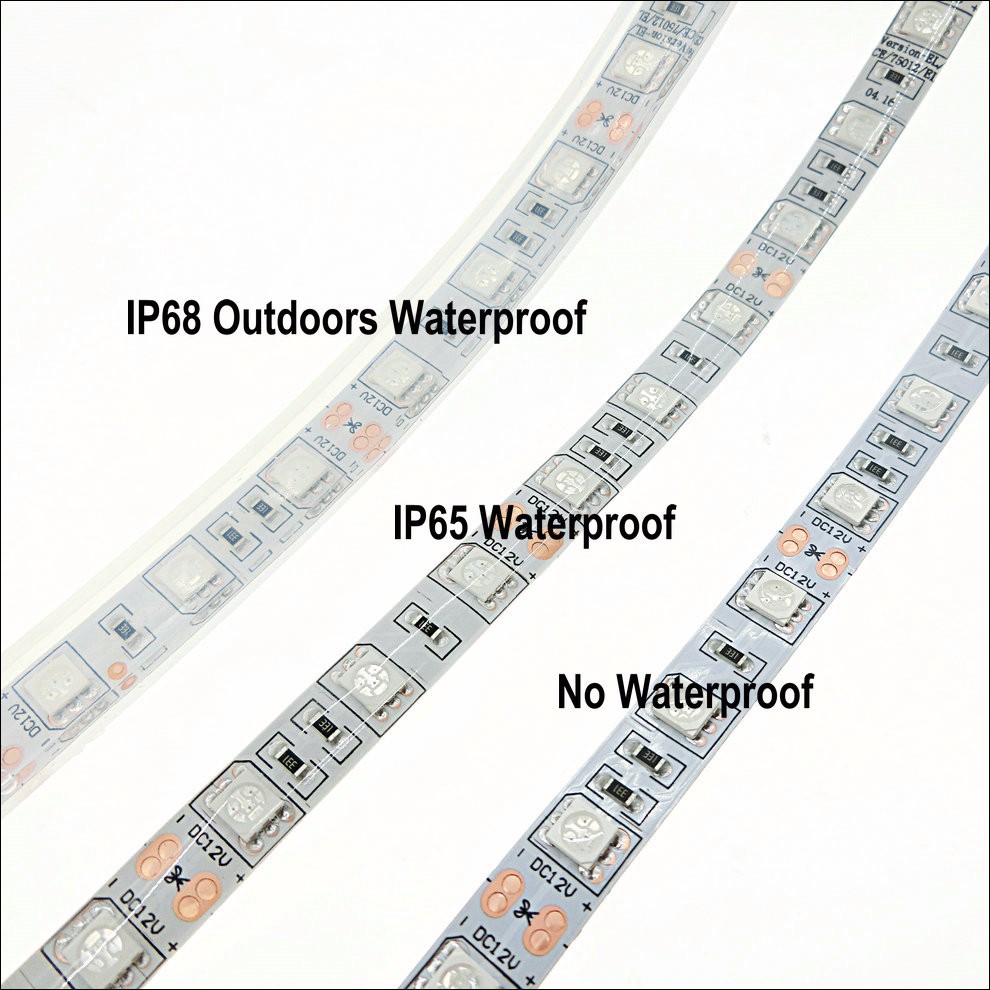

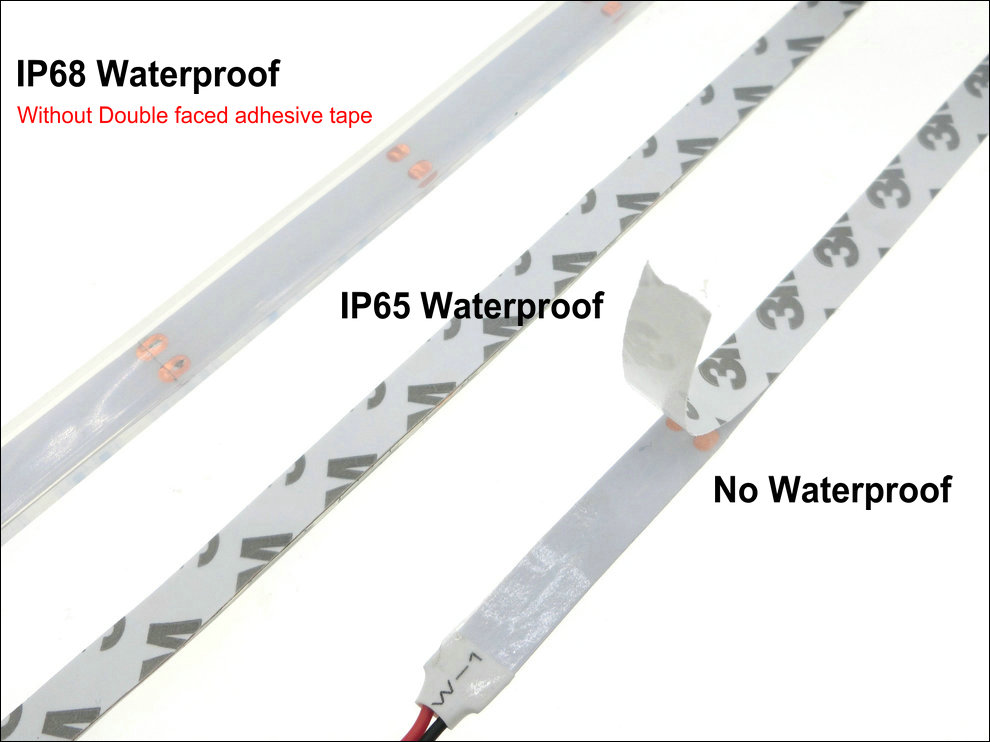

3. Protection Rate: IP65 Waterproof / IP20 No Waterproof

4. Working Voltage: 12V DC

5. LED Quantity: 60leds/meter

6. Red:Blue = 3:1 / Red:Blue = 4:1 / Red:Blue = 5:1 / Red:Blue:White = 4:1:1 etc

( LED Color combination and ratio can be customized as the request )

7. The Strips length can be customized as per the request

Features:

1. Super bright 5050 SMD LED with 3Chips, high intensity and reliability.

2. Long life span more than 50,000 hours

3. Continuous length, packed with 5 meter.

4. Flexible ribbon for curving around bends

5. Completely smooth and even light spread, solving the uneven luminous problem

6. Ultra-bright but running at low temperature

7. Low power consumption, Comfortable, Humanistic & High-performing

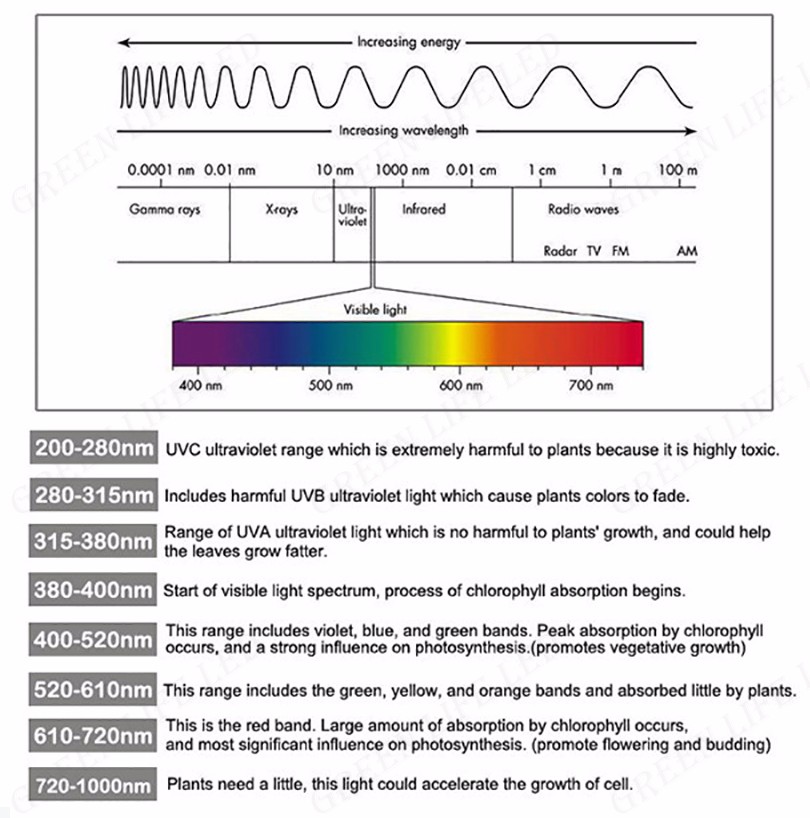

Spectral range effects on plant physiology:

280nm ~ 315nm influence on morphological and physiological processes is minimal

315 nm ~ 420nm chlorophyll absorbs less impact photoperiod effect, prevent stem elongation

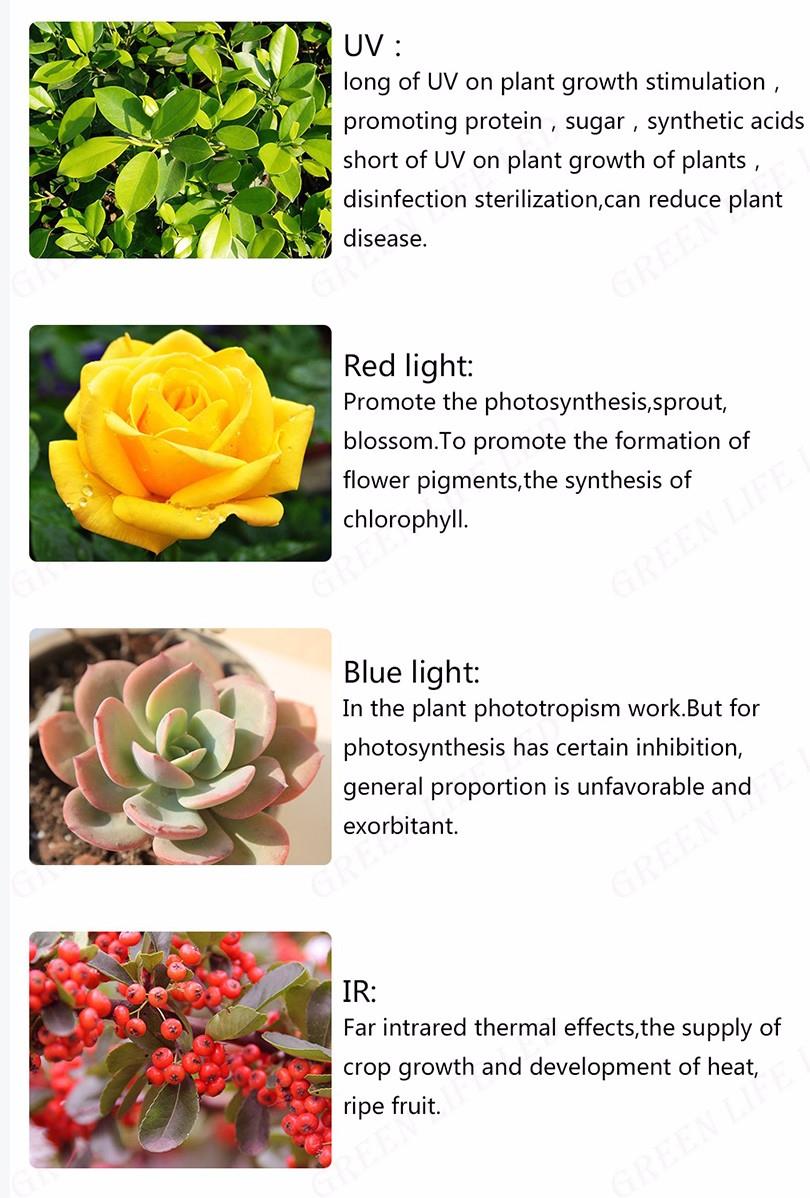

420 nm ~ 500nm (blue) chlorophyll and carotenoids absorbed the largest proportion, the greatest impact on photosynthesis

500 nm ~ 620nm dye absorption rate is not high

620nm ~ 750nm (red) chlorophyll absorption rate "high", has a significant influence on photosynthesis and photoperiod effect

750nm ~ 1000nm absorption rate, stimulate cell elongation, impact of flowering and seed germination

> 1000nm converted into calorie

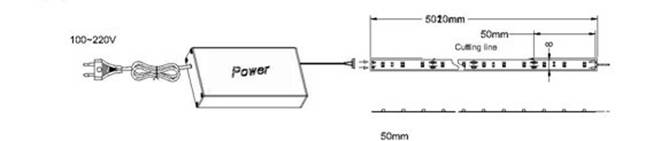

The Driver:

Match the different Power Driver as per the different length strips

Package:

5meters is packed in 1 roll generally, the length can be customized as per the request

Application:

Perfect for the seedling tissue culture, the hydroponics, seeding plants growing... etc

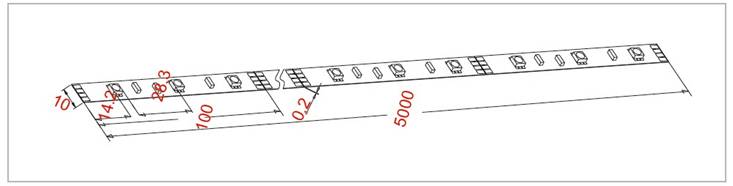

Dimension (mm):

Safety Information:

* The strip itself and all its components may not be mechanically stressed.

* Assembly must not damage or destroy conducting paths on the circuit board.

* Installation of LED ribbon (with power supplies) needs to be made with regard to all applicable electrical and safety standards. Only qualified personnel should be allowed to perform installations.

* Correct electrical polarity needs to be observed. Wrong polarity may destroy the strip.

* Parallel connection is highly recommended as safe electrical operation mode.

* Serial connection is not recommended. Unbalanced voltage drop can cause hazardous overload and damage the strip.

* Please ensure that the power supply is of adapters power to operate the total load.

* When mounting on metallic or otherwise conductive surfaces, there needs to be an electrical isolation points between strip and the mounting surface.

* Pay attention to standard ESD precautions when installing the strip.

* Damaged by corrosion will not be honored as a materials defect claim. It is the user's responsibility to provide suitable protection against corrosive agents such as moisture and condensation and other harmful elements.